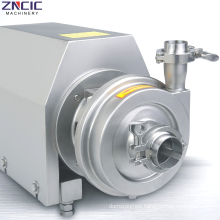

High Quality Slurry Discharge Transfer Pump

Product Description

Working Pressure: High Pressure Pump Position of Pump Shaft: Vertical Pump Mounting Height: Suction Centrifugal Usage: Ash Pumps Trademark: HENGNUO Specification: GB11035-89; ISO9001; CE HS Code: 8413604090 Influent Type of Impeller: Single Suction Pump Pump Casing Combined: Horizontal Split Pumps Impeller: Open Pressure Medium: Oil Transport Package: Marine Wooden Case Origin: Cangzhou High rigidity particle mining pump slurry pump sand pump

1. Durable slurry pump used for mines and industry solids pumping.

2. Slurry pump drive module design which makes the spare parts can be changed easily

3. Designed and built for long time with low maintenance for the Heavy brand slurry pump

4. Equipped the electric motor or diesel engine with slurry pump according to your requirement

5. Long service life for the wet parts of slurry pump.

The Features:

1. The wet parts for slurry pump are made of wear-resistant chromium alloy.

2. Slurry pump's bearing assembly use cylindrical structure,adjusting the space between impeller

andfront liner easily, they can be removed completely when being repaired. Bearing assembly use

grease lubrication.

3. The shaft seal could use the packing seal, expeller seal and mechanical seal.

4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any

eight positions to suit installations and applications.

5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, frequency

conversion drive devices for the slurry pump.

6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in

multistage series to meet the delivery for long distance.

More Specifications:

1.Type HS slurry pumps are cantilevered, horizontal, centrifugal dredge slurry pumps. They

are designed for handling abrasive, high density slurry in the metallurgical, mining, coal,

power, building material and other industrial departments etc.

2.According the different woking conditions, the wearing parts for type HS slurry pumps are

interchangeable, hard metal or pressure molded elastomeric liners.

3.Its key parts are made of anti-wear and anti-corrosive materials. It has many advantages,

such as, long service life, smooth running, leakage-free and easy maintenance.

4.HS series slurry pumps are used to pump high-hardness, strong-corrosion and high-

concentration liquids that contain suspended solid particles, such as finished ores, refuse ores,

ashes, cinders, cements, mud, mineral stones and etc. in the industries of metallurgy, mining,

coal, power, building material and etc. The temperature of the pumped solid-liquid mixture

should be ≤80oC, and the weight concentration should be ≤60.

The concept of our company is based on the elite and technology, creating the highest-quality product and service, making the most contribution to the society.

It shows that our company is an enterprise which puts the elite in the most important position, bringing up and developing the elite. In order to let the staff keep up with the developing society and show their best personal qualities, we have been always encouraging them to dig up their abilities and make them the creative and open-minded person.

In other words, our company goal lies in developing the great technology, which can create the happiness for the human beings and devote themselves to the society through cultivating the elite.

Meantime, with the application of the elite and the new technology, our company is devoted to being a responsibility management enterprise. All of the activities take place with the involvement of promoting the prosperities of the society and the human beings. To realize the aims, we are putting our great efforts in it.

Case:

The thickness of the shell:

300 pound wall thickness as standard, increasing the reliability

and extend the life of maximizing housing. Top centerline discharge

and self-ventilation air. Serrated flange to achieve an effective seal.

Ductile Iron Adapter:

Material strength equivalent to steel security and reliability.

Heavy duty shaft and bearing:

Rigid shaft design in harsh conditions, bearing an average life expectancy

of 10 years.

Standard labyrinth seal:

Prevent oil contamination or damage caused premature bearing failure,

lower bearing operating temperatures, longer service life.

Screws from the top:

The axial position can be adjusted, saving maintenance costs.

Bull's-eye observation window:

Ensure the proper oil level is essential to the life of the bearing, the choice oiler.

Large tank:

Large oil can improve the cooling performance, reduce the oil temperature,

the better cooling effect of the bearing, thus prolonging the life.

Rigid support:

Reduce the impact load on the pipe axis calibration, reducing pump vibration.

Flexible seal:

Suitable for a wide range of solutions to meet a variety of seal conditions.

Shaft sealing specially designed to improve the seal side lubrication

and radiating (cooling), to extending seal life and trouble-free pump life.

Fully open impeller:

Fully open impeller with greater wear surface, can extand life,

but performance can be restored, reducing maintenance costs,

the lowest hydraulic loading, the maximum mechanical reliability.

Contact us if you need more details on Sand Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sand Centrifugal Pump、Centrifugal Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Sand Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sand Centrifugal Pump、Centrifugal Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Durable slurry pump used for mines and industry solids pumping.

2. Slurry pump drive module design which makes the spare parts can be changed easily

3. Designed and built for long time with low maintenance for the Heavy brand slurry pump

4. Equipped the electric motor or diesel engine with slurry pump according to your requirement

5. Long service life for the wet parts of slurry pump.

The Features:

1. The wet parts for slurry pump are made of wear-resistant chromium alloy.

2. Slurry pump's bearing assembly use cylindrical structure,adjusting the space between impeller

andfront liner easily, they can be removed completely when being repaired. Bearing assembly use

grease lubrication.

3. The shaft seal could use the packing seal, expeller seal and mechanical seal.

4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any

eight positions to suit installations and applications.

5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, frequency

conversion drive devices for the slurry pump.

6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in

multistage series to meet the delivery for long distance.

More Specifications:

1.Type HS slurry pumps are cantilevered, horizontal, centrifugal dredge slurry pumps. They

are designed for handling abrasive, high density slurry in the metallurgical, mining, coal,

power, building material and other industrial departments etc.

2.According the different woking conditions, the wearing parts for type HS slurry pumps are

interchangeable, hard metal or pressure molded elastomeric liners.

3.Its key parts are made of anti-wear and anti-corrosive materials. It has many advantages,

such as, long service life, smooth running, leakage-free and easy maintenance.

4.HS series slurry pumps are used to pump high-hardness, strong-corrosion and high-

concentration liquids that contain suspended solid particles, such as finished ores, refuse ores,

ashes, cinders, cements, mud, mineral stones and etc. in the industries of metallurgy, mining,

coal, power, building material and etc. The temperature of the pumped solid-liquid mixture

should be ≤80oC, and the weight concentration should be ≤60.

The concept of our company is based on the elite and technology, creating the highest-quality product and service, making the most contribution to the society.

It shows that our company is an enterprise which puts the elite in the most important position, bringing up and developing the elite. In order to let the staff keep up with the developing society and show their best personal qualities, we have been always encouraging them to dig up their abilities and make them the creative and open-minded person.

In other words, our company goal lies in developing the great technology, which can create the happiness for the human beings and devote themselves to the society through cultivating the elite.

Meantime, with the application of the elite and the new technology, our company is devoted to being a responsibility management enterprise. All of the activities take place with the involvement of promoting the prosperities of the society and the human beings. To realize the aims, we are putting our great efforts in it.

Case:

The thickness of the shell:

300 pound wall thickness as standard, increasing the reliability

and extend the life of maximizing housing. Top centerline discharge

and self-ventilation air. Serrated flange to achieve an effective seal.

Ductile Iron Adapter:

Material strength equivalent to steel security and reliability.

Heavy duty shaft and bearing:

Rigid shaft design in harsh conditions, bearing an average life expectancy

of 10 years.

Standard labyrinth seal:

Prevent oil contamination or damage caused premature bearing failure,

lower bearing operating temperatures, longer service life.

Screws from the top:

The axial position can be adjusted, saving maintenance costs.

Bull's-eye observation window:

Ensure the proper oil level is essential to the life of the bearing, the choice oiler.

Large tank:

Large oil can improve the cooling performance, reduce the oil temperature,

the better cooling effect of the bearing, thus prolonging the life.

Rigid support:

Reduce the impact load on the pipe axis calibration, reducing pump vibration.

Flexible seal:

Suitable for a wide range of solutions to meet a variety of seal conditions.

Shaft sealing specially designed to improve the seal side lubrication

and radiating (cooling), to extending seal life and trouble-free pump life.

Fully open impeller:

Fully open impeller with greater wear surface, can extand life,

but performance can be restored, reducing maintenance costs,

the lowest hydraulic loading, the maximum mechanical reliability.

Contact us if you need more details on Sand Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sand Centrifugal Pump、Centrifugal Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Sand Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sand Centrifugal Pump、Centrifugal Pump. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Centrifugal Pump

Premium Related Products

Other Products

Hot Products

NYP Series Internal Gear Pump With Heating JacketYCB Series Stainless Steel Gear PumpCYZ Series Self-Priming Centrifugal Pump With Diesel EngineKCB series oil transfer gear pump pumping equipment for various viscosity liquid1/2 inch to 1 inch sanitary stainless steel rotary lobe pump for food industryhot oil boiler centrifugal submersible pump with stainless steel impeller pumpfood gear pump goods in stock good qualityYHCB(YPB) series fuel oil rotary vane pumpCYZ type self-priming gasoline centrifugal oil pump for saleHigh flow electric driven explosion proof fuel oil transfer pumpWidely used in industry gear type self priming pump made in China made in ChinaSaving room belt and pulley driven progressive cavity mono screw pumps for food marineBosin good quality electric oil pump 12V electric oil pump 12VBosin 2BV water/liquid ring vacuum pump 2BV2060Bosin Pump NYP type high viscosity internal gear pumpKCB/2CY series gear oil pump for transportation/chemical processing pump/positive displacement pump